Skip to content

Features

Type: Non-contact magnetic linear encoder (measures displacement without physical contact)

Measuring length: Up to 50 meters

Function: Converts linear movements of machine components into electrical signals with information about:

Value: Distance travelled

Direction: Forward or backward movement

Durability: Designed for harsh industrial environments and resistant to various contaminants and physical impacts.

Components:

Metal-based magnetic band (MP): Stores the encoded information

Reading head: Detects the magnetic field variations on the band and converts them into electrical signals

Profile rail (PS) with protective band: Provides mounting and protects the reading head

Features

Type: Photoelectric linear displacement measuring device (measures changes in position)

Measuring length: Up to 2.040 mm

Grating period: Two options available: ±20 µm or ±40 µm (determines the smallest detectable movement)

Accuracy: Up to ±3 µm (indicates the encoder's closeness to the actual displacement)

Features

Measuring length: Up to 3.240 mm

Accuracy: Up to ±5 µm within any meter of its measuring length

Grating periods: Available in two options: ±20 µm and ±40 µm

Features

Similar to the L18 series: Shares most functionalities and specifications with the L18 series encoders.

Different housing fixation: Requires distinct mounting methods compared to the L18 series.

Improved thermal behaviour: More stable performance under different temperatures.

Features

Type: Photoelectric modular linear encoder

Measuring length:

Up to 20,000 mm (20 meters)

Can be even longer with special order

Accuracy: Up to ±3 µm

Features

Type: Incremental linear displacement measuring device (measures changes in position)

Measuring length: Up to 3.240 mm

Accuracy: Up to ±3 µm within any meter of its measuring length (accuracy scales with length)

Vibration resistance: More resistant to vibrations than the L18 series encoders

Features

Similar to the L35 series: Shares most functionalities and specifications with the L35 series encoders.

Different mounting parameters: Requires distinct mounting methods compared to the L35 series.

Measuring length: Up to 3.240 mm.

Enhanced vibration resistance: More resistant to vibrations than the L18 series encoders, making it suitable for applications with higher vibration levels.

Features

Type: Incremental encoder

Thermal behaviour: Reproducible, indicating stability under temperature changes

Reading head: Reversible for flexibility in installation

Measuring length: Up to 3.240 mm

Accuracy: Up to ±3 µm within the measuring length

Features

Type: Incremental encoder

Measuring length: 3.240 mm to 30.040 mm

Grating period: 40 µm

Accuracy: Up to ±10 µm within the measuring length

Features

Type: Photoelectric absolute linear encoder (measures absolute position)

Measuring length: Up to 3.240 mm (customizable)

Interface: SSI or BiSS serial interface for digital communication

Accuracy: Up to ±1 µm high accuracy

Optional incremental track: Provides 1Vpp incremental signal for applications requiring both absolute and incremental position data.

Features

Magnetic absolute linear encoder

MK has a measuring length of up to 50.000 mm

Accuracy can reach up to ±35 μm.

Encoder has two versions of serial interface - SSI or BiSS C

Optionally it can have 2 analog sinusoidal signals with phase shift 90°C and amplitude approx. 1Vpp.

Features

Measuring length: Up to 50,000 mm (50 meters)

Accuracy: Up to ±25 micrometres (μm)

Customizable: Other parameters can be modified to meet specific needs

Features

Converts the movement of key machine parts into electrical signals.

Designed for harsh industrial environments and resistant to various physical and environmental factors.

Magnetic band length can reach up to 50 meters.

Allows for either user-defined reference marks or external zero signal actuator.

LED on the reading head confirms reference mark detection.

Compressed air can be used to clean the rail surface, improving accuracy.

Two output signal options:

PCMT-F: Square-wave with built-in interpolation electronics.

PCMT-AV: Sinusoidal signal requiring external interpolation.

Features

Individual scalable process or speed indicator

Dual channel frequency indicator for visualization of the encoder frequency

Display of alarm and error codes

Touch screen with intuitive menu guidance

1.54" OLED Display (128 x 64 Pixel)

Dimension: 50 x 80 x 15 mm (1,97 x 3,15 x 0,59")

Features

Simple parameterization of motrona safety devices

Editing, saving and loading of parameters

Individual scalable process or speed indicator

Dual channel frequency indicator for visualization of the encoder frequency

Touch screen with intuitive menu guidance

1.54" OLED Display (128 x 64 Pixel)

Dimension: 50 x 80 x 15 mm (1,97 x 3,15 x 0,59")

Features

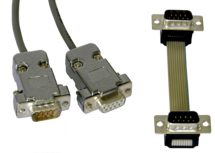

USB to RS232 converter (compatible with all existing Windows versions)

Serial RS232 cable (for connection between the converter and motrona unit)

One connector Sub-D-9 (male)

One connector Sub-D-9 (female)

Length 3 m (approx. 10 feet)

Windows driver CD enclosed

Features

2 pulse inputs with format A, B, 90° [HTL] or A, /A, B, /B [RS422]

4 control inputs for HTL / PNP / NPN / Namur signals [10 ... 30 VDC]

Input frequency up to 300 kHz

4 fast transistor outputs, push-pull, short-circuit-proof [5 … 30 VDC]

1 scalable 14-bit analog output (±10 V or 0/4 … 20 mA)

Loop time approx. 250 µs

Cutting length specification via keyboard Power supply 24 VAC and 17 … 40 VDC

Compact norm panel housing (according to EN 60715)

Top hat rail mounting by using SM300 support brackets (option)

Setup via keys or via PC by serial RS232 interface

PROFIBUS connection via Motrona gateway PB251

Features

2 pulse inputs with format A, B, 90° [HTL] or A, /A, B, /B [RS422]

4 control inputs for HTL / PNP / NPN / Namur signals [10 ... 30 VDC]

Input frequency up to 300 kHz

4 fast transistor outputs, push-pull, short-circuit-proof [5 … 30 VDC]

4 potential-free changeover relay outputs

1 scalable 14-bit analog output (±10 V or 0/4 … 20 mA)

Loop time approx. 250 µs

Cutting length specification via BCD decade switch on the front

Power supply 24 VAC and 17 … 40 VDC

Compact norm panel housing (according to EN 60715)

Top hat rail mounting by using SM600 support brackets (option)

Setup via keys or via PC by serial RS232 interface

PROFIBUS connection via Motrona gateway PB251

Features

SIL3 and PLe certification

Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

2 encoder inputs with format SIN+, SIN-, COS+, COS- [1 Vss]

2 pulse inputs with format A, /A, B, /B [RS422]

2 pulse- or control inputs with format A, B, 90° [HTL / PNP] (for rotary encoder, proximity switches or commands)

Input frequency up to 500 kHz

Forced-guided redundant output relay (NO)

4 control outputs with push-pull characteristic, short-circuit-proof, [HTL], each inverse and redundant

Safety related 14 bit analog output for 4 ... 20 mA (scalable)

With signal splitter

Power supply 18 ... 30 V

Compact housing for 35 mm mounting top hat rail

(according to EN 60715)

Setup via USB port by operator software or plug-in display and programming unit BG230 (accessories)

Features

SIL3 and PLe certification

Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

2 encoder inputs with format SIN+, SIN-, COS+, COS- [1 Vss]

2 pulse inputs with format A, /A, B, /B [RS422]

2 pulse- or control inputs with format A, B, 90° [HTL / PNP] (for rotary encoder, proximity switches or commands)

Input frequency up to 500 kHz

Forced-guided redundant output relay (NO)

4 control outputs with push-pull characteristics, short-circuit-proof, [HTL], each inverse and redundant

Safety-related 14-bit analogue output for 4 ... 20 mA (scalable)

Power supply 18 ... 30 V

Compact housing for 35 mm mounting top-hat rail (according to EN 60715)

Setup via USB port by operator software or plug-in display and programming unit BG230 (accessories)

Features

SIL3 PLe Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

2 encoder input with format SIN+, SIN-, COS+, COS- [1 Vss]

2 pulse- or control inputs with format A, B, 90° [HTL / PNP] (for rotary encoder, proximity switches or commands)

Input frequency up to 500 kHz

Forced-guided redundant output relay (NO)

4 control outputs with push-pull characteristic, short-circuit-proof, [HTL], each inverse and redundant

Safety-related 14-bit analogue output for 4 ... 20 mA (scalable)

With signal splitter

Power supply 18 ... 30 V

Compact housing for 35 mm mounting top hat rail (according to EN 60715)

Setup via USB port by operator software or plug-in display and programming unit BG230

Features

SIL3/PLe Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

2 encoder input with format SIN+, SIN-, COS+, COS- [1 Vss]

2 pulse inputs with format A, /A, B, /B [RS422]

2 pulse- or control inputs with format A, B, 90° [HTL / PNP] (for rotary encoder, proximity switches or commands)

Input frequency up to 500 kHz

Forced-guided redundant output relay (NO)

4 control outputs with push-pull characteristic, short-circuit-proof, [HTL], each inverse and redundant

Safety-related 14-bit analog output for 4 ... 20 mA (scalable)

Power supply 18 ... 30 V

Compact housing for 35 mm mounting top hat rail (according to EN 60715)

Setup via USB port by operator software or plug-in display and programming unit BG230

Features

SIL3 and PLe certification

Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

2 incremental encoder inputs with format A, /A, B, /B, Z, /Z [HTL differencial, HTL single ended, RS422]

8 control inputs [HTL / PNP]

Input frequency up to 500 kHz

2 relay outputs 5... 250 VAC / VDC (NO)

4 x 2 control outputs with push-pull characteristic, short-circuit-proof, [HTL], antivalent or equivalent redundant or simply used

Safety related 14 bit analog output for 4 ... 20 mA (scalable)

Signal splitter

Power supply 18 ... 30 V

Wire monitoring of the sensor signals

Compact housing for 35 mm mounting top hat rail (according to EN 60715)

USB interface in combination with the user interface OS6.0 for the parameterization of the safety speed monitor

BG200 operator panel for easy parameterization and display (optional)

Features

SIL3 and PLe certification (depends on the used encoder/sensor arrangement)

Safety functions equivalent to EN 61800-5-2 (SS1, SS2, SOS, SLS, SDl, SSM, SLI, SBC, STO, SMS)

1 incremental encoder input with format A, /A, B, /B, Z, /Z [HTL differencial, RS422]

8 control inputs [HTL / PNP]

Input frequency up to 500 kHz

2 relay outputs 5... 250 VAC / VDC (NO)

4 x 2 control outputs with push-pull characteristic, short-circuit-proof, [HTL], antivalent or equivalent redundant or simply used

Safety related 14 bit analog output for 4 ... 20 mA (scalable)

Signal splitter

Power supply 18 ... 30 V

Wire monitoring of the sensor signals

Compact housing for 35 mm mounting top hat rail (according to EN 60715)

USB interface in combination with the user interface OS6.0 for the parameterization of the safety speed monitor

BG200 operator panel for easy parameterization and display (optional)

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 500 kHz

2 output relays with potential-free change-over contact (forward, reward and zero motion)

2 transistor outputs with High-Side-Driver, short-circuit-proof

Power supply 17 ... 30 VDC

Snap-on housing for top hat rail (according to EN 60715)

DIL switch for setup of input characteristic and definition of standstill

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 1 MHz

3 output relays

14 Bit analog output for ±10 V or 0/4 ... 20 mA

Power supply 17 ... 30 VDC

Auxiliary voltage output +5 V for the supply of TTL encoders

Snap-on housing for top hat rail (according to EN 60715)

LCD display, backlighted

Setup via keys or via PC by serial RS232 interface

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 1 MHz

3 fast transistor switching outputs [PNP]

14 bit analog output for ±10 V or 0/4 ... 20 mA

Power supply 17 ... 30 VDC

Auxiliary voltage output +5 V for the supply of TTL encoders

Snap-on housing for top hat rail (according to EN 60715)

LCD display, backlighted

Setup via keys or via PC by serial RS232 interface

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 1 MHz

14 bit analog output for ±10 V or 0/4 ... 20 mA

Power supply 17 ... 30 VDC

Auxiliary voltage output +5 V for the supply of TTL encoders

Snap-on housing for top hat rail (according to EN 60715)

LCD display, backlighted

Setup via keys or via PC by serial RS232 interface

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 1 MHz

3 output relays

Power supply 17 ... 30 VDC

Auxiliary voltage output +5 V for the supply of TTL encoders

Snap-on housing for top hat rail (according to EN 60715)

LCD display, backlighted

Setup via keys or via PC by serial RS232 interface

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B [RS422], also possible for single-channel

Input frequency up to 1 MHz

3 output relays

Power supply 17 ... 30 VDC

Auxiliary voltage output +5 V for the supply of TTL encoders

Snap-on housing for top hat rail (according to EN 60715)

LCD display, backlighted

Setup via keys or via PC by serial RS232 interface

Features

Sub-D-9 connectors (male) on both sides

cable length 10 cm (approx. 3.4")

Features

Pulse input with format A, B, Z [HTL single-ended, TTL single-ended] or A, /A, B, /B, Z, /Z [RS422, HTL differential]

4 control inputs for HTL, PNP signals [10 ... 30 VDC]

Input and output frequency up to 1 MHz

3 incremental outputs with format A, /A, B, /B, Z, /Z, Push-Pull, [8 … 29 VDC]

Power supply 9 ... 30 VDC

Snap-on housing for top-hat rail (acc. EN 60715)

Multiplier/divisor adjustable as quotient F1 / F2

Multiplication/division without cumulative residual errors

Additional functions such as jog, trim, offset and reference

Features

Pulse input with format A, B, 90° [HTL] or A, /A, B, /B, Z, /Z [RS422]

4 control inputs for PNP signals [10 ... 30 VDC]

Input and output frequency up to 1 MHz

Pulse output with format A, /A, B, /B, Z, /Z and

push-pull characteristic, [5 ... 30 VDC]

Power supply 11 ... 30 VDC

Snap-on housing for top-hat rail (according to EN 60715)

LCD backlighted

Setup via keys, RS232

The device multiplies an incoming frequency by a proportional factor F1 and a reciprocal factor F2. The two factors F1 and F2 are adjustable in the range of 0.0005 to 9.9999

All operation modes provide error-free frequency conversion, with full consideration of the A / B phase and direction of the quadrature signals, therefore no cumulative errors, even with continuous changes of directions and vibrations

Zero pulse generator: the frequency multiplier generates at the output an index signal with an adjustable pulse interval, which can be synchronized as needed with the zero pulse at the input

Features

Pulse input in format A, /A, B, /B, Z, /Z [RS422, HTL]

Pulse input in format A, B, Z [HTL]

Input frequency up to 1 MHz

Pulse output in format A, /A, B, /B, Z, /Z [RS422, HTL]

Pulse output in format A, B, Z [HTL]

Power supply 9 ... 30 VDC

Settings via DIL switches

Level conversion (RS422, HTL single-ended, HTL differential, TTL and vice versa)

Division of two-track A / B pulses with adjustable ratio 1: 1 to 1: 4096

Division of the Z pulse with adjustable ratio 1: 1 to 1: 256

External HTL signals for various functions

Implementation between the two types of representations for the direction of rotation (A / B 90 °, A/B Dir and vice versa, Division possible)

Snap-on housing for top-hat rail (acc. EN 60715)

Dimension (B x H X T) 22,5 x 102 x 102 mm

Features

4 pulse inputs with format A, /A, B, /B [RS422]

4 scalable 12-bit analog inputs for ±10 V or 0/4 ... 20 mA

8 control inputs for PNP signals [10 ... 30 VDC]

4 scalable 12-bit analog outputs for ±10 V or 0/4 ... 20 mA

Short loop time (depending on application)

Power supply 18 ... 35 VDC

Snap-on housing for top-hat rail (according to EN 60715)

Setup via Windows operator software (free of charge)

OnBoard interfaces: RS232 and CANopen

Features

The MC800 hardware is a universal motion controller, which serves for sophisticated control tasks in today’s machine engineering and drive technology. This motion controller can cover a wide application range due to the function features and settings of the equipped control firmware.

Typical control applications are e.g. drive synchronization of a master and slave axis, index and print mark evaluation, rotating cross cutters, flying and eccentric shears, label printing machines and many more.

The unique feature of the MC800 is the integrated tandem drive controller. This enables to reach the acceleration requirements of heavy loads by splitting the necessary power to two independent drives.

Further features are the flexible and combinable input configuration for different types of encoders, measuring systems and sensors, the high frequency range up to 2 MHz and the adaptive interface architecture.

Due to an extremely short position loop time of 250 µs, a self-optimizing polynomial motion profile, and excellent accuracy - even at high line speeds, the MC800 ensures a very smooth motion with maximum protection of the mechanical parts.

Page load link